Description

Brief Summary of Unit:

This unit has just had a comprehensive scope of works carried out (please see summary below). The machine had full cosmetic refurbishment (including full blast/paint) post-completion of the mechanical work scope. Unit is fully Australian mine compliant. Boom/stick had MPI carried out with under 500 hours on all other main hydraulic hoses (boom/stick/bucket/arch/HP Pump hoses).

Brief Summary of work scope that has just been completed:

1 – Removed all panels, covers, walkways, access doors, etc.

2 – Carried out full Blast and paint (2 Pac).

3 – Fabricate, blast, paint and fit all new exterior paneling, skirting and covers.

4 – Carried out a full overhaul of cab group (strip/prep/blast and paint, new front glass, all new glass rubbers, new interior linings, etc.).

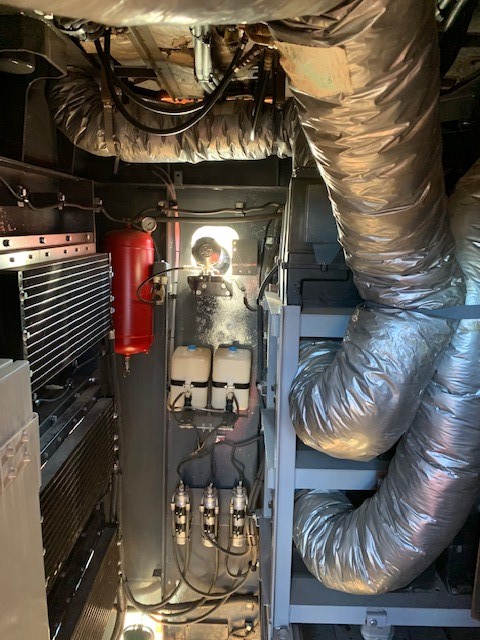

5 – Carried out a full overhaul of the 3 x air conditioner systems.

6 – Fitted new operators’ seat group.

7 – Reworked battery box compartment, fitted 4 x new batteries.

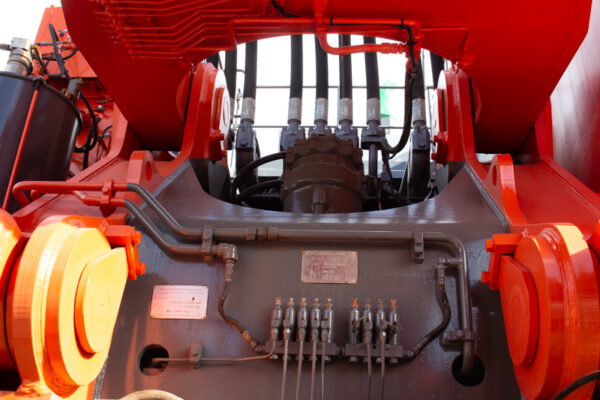

8 – O/Hauled, serviced auto lube system (Fitted with Bard Engineering lube system).

9 – fitted updated engine crankshaft front seal group.

10 – Overhauled, blast and paint assess ladder group, fitted new proximity switch group.

11 – Stripped, prepped, blasted and painted engine air intake module (fitted new air cleaners).

12 – Checked, inspected, tested, tidied up, and repaired as necessary all electrical circuits, looms, componentry, etc.

13 – stripped out, prepped, blast and paint inside of cab riser,

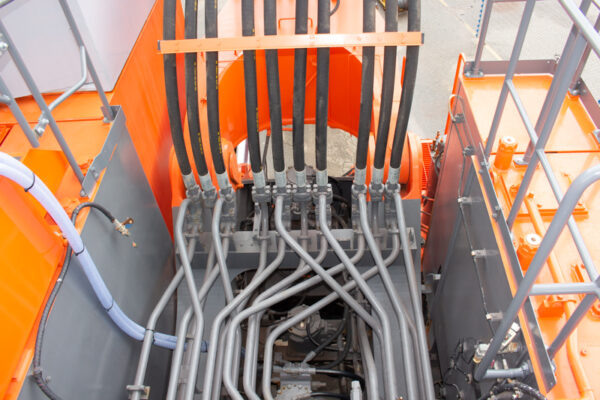

14 – Stick ..Stripped, blasted, cracked tested, fitted new grease channel sections and painted, fitted all new pin grease seals, re-shimmed all linkages, fitted new trust plates on the nose.

15 – Fitted new alternator and drive belt.

16 – Fitted all new hoses to/from the radiator expansion tank.

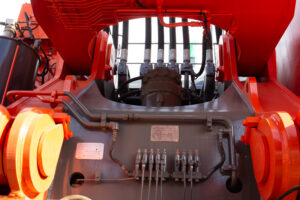

17 – Replaced oil return hoses on front and rear hydraulic swivel groups.

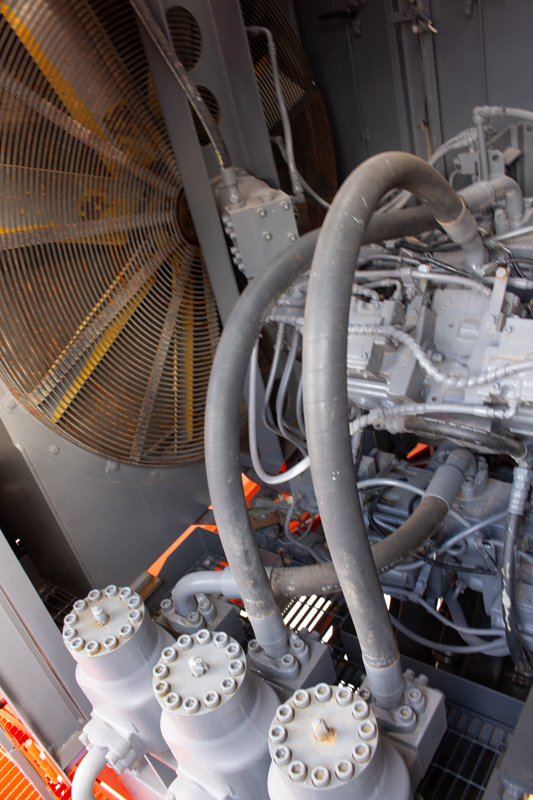

18 – Fitted reconditioned hydraulic cooler GP

Brief Summary of work scope that has just been completed:

1 – Removed all panels, covers, walkways, access doors, etc.

2 – Carried out full Blast and paint (2 Pac).

3 – Fabricate, blast, paint and fit all new exterior paneling, skirting and covers.

4 – Carried out a full overhaul of cab group (strip/prep/blast and paint, new front glass, all new glass rubbers, new interior linings, etc.).

5 – Carried out a full overhaul of the 3 x air conditioner systems.

6 – Fitted new operators’ seat group.

7 – Reworked battery box compartment, fitted 4 x new batteries.

8 – O/Hauled, serviced auto lube system (Fitted with Bard Engineering lube system).

9 – fitted updated engine crankshaft front seal group.

10 – Overhauled, blast and paint assess ladder group, fitted new proximity switch group.

11 – Stripped, prepped, blasted and painted engine air intake module (fitted new air cleaners).

12 – Checked, inspected, tested, tidied up, and repaired as necessary all electrical circuits, looms, componentry, etc.

13 – stripped out, prepped, blast and paint inside of cab riser,

14 – Stick ..Stripped, blasted, cracked tested, fitted new grease channel sections and painted, fitted all new pin grease seals, re-shimmed all linkages, fitted new trust plates on the nose.

15 – Fitted new alternator and drive belt.

16 – Fitted all new hoses to/from the radiator expansion tank.

17 – Replaced oil return hoses on front and rear hydraulic swivel groups.

18 – Fitted reconditioned hydraulic cooler GP

Configuration: Excavator

Serial Number: HCM18C00K00000132

OEM Code: OEMUE0178

YOM: 2004

Shipping Information: In shipping configuration and delivered (FAS) to Fremantle Port Western Australia available on request.

Machine Location: Perth, Western Australia (closest port is Fremantle).

Reviews

There are no reviews yet.